Plate flanges are crucial components in various piping and industrial systems, providing a secure and efficient means of connecting pipes, valves, and other equipment. This article delves into what plate flanges are, the different types available, and their diverse uses across industries.

What Are Plate Flanges?

Plate flanges are flat, circular discs with a hole in the center, used to connect two sections of pipe or other equipment. They are typically made from materials such as steel, stainless steel, or plastic and come in various sizes and thicknesses to accommodate different applications.

Key Features of Plate Flanges

- Flat Surface: Provides a stable connection surface for bolting.

- Central Hole: Allows the flange to be mounted onto a pipe or equipment.

- Bolt Holes: Arranged around the flange to secure it with bolts.

Types of Plate Flanges

1. Flat Face Plate Flanges

Features:

- Flat Surface: Provides even contact with the gasket.

- Simple Design: Suitable for low-pressure applications.

- Cost-Effective: Generally less expensive than raised face flanges.

Applications:

- Water treatment systems

- HVAC systems

- Low-pressure piping

2. Raised Face Plate Flanges

Features:

- Raised Surface: Offers a larger area for gasket compression.

- High-Pressure Use: Ideal for high-pressure and high-temperature applications.

- Enhanced Sealing: Provides a better seal compared to flat face flanges.

Applications:

- Oil and gas pipelines

- Chemical processing plants

- High-pressure steam lines

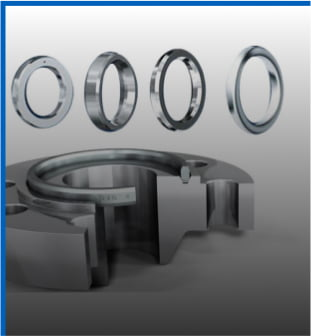

3. Ring Type Joint Plate Flanges

Features:

- Metal-to-Metal Seal: Ensures a high-integrity, leak-proof connection.

- Precise Machining: Requires exact manufacturing for effective sealing.

- High Pressure and Temperature: Suitable for extreme conditions.

Applications:

- High-pressure steam systems

- Petrochemical industries

- Offshore platforms

4. Blind Plate Flanges

Features:

- Closed Design: Used to block off a pipeline or vessel.

- No Central Hole: Provides a solid barrier to pressure.

- Varied Sizes: Available in various diameters and thicknesses.

Applications:

- Maintenance and inspection points

- Temporary system closures

- End caps for piping systems

Uses of Plate Flanges

1. Pipeline Connections

Plate flanges are widely used to connect sections of pipelines, ensuring a secure and leak-proof connection. They are essential in industries such as oil and gas, water treatment, and chemical processing.

2. Equipment Mounting

In addition to pipelines, plate flanges are used to mount equipment like pumps, valves, and tanks. They provide a stable and reliable connection point, facilitating easy installation and maintenance.

3. System Modifications

Plate flanges are crucial for system modifications, allowing for easy disassembly and reconfiguration. They enable the addition or removal of pipeline sections or equipment without extensive system overhauls.

4. Pressure Containment

In high-pressure systems, plate flanges help contain and manage pressure, preventing leaks and ensuring system safety. They are used in various high-pressure applications, including steam lines and chemical reactors.

FAQs

1. What are the main types of plate flanges?

- The main types include flat face, raised face, ring type joint, and blind plate flanges.

2. How do flat face plate flanges differ from raised face plate flanges?

- Flat face flanges have a flat surface for gasket compression, suitable for low-pressure applications, while raised face flanges have a raised area for better sealing in high-pressure applications.

3. What are ring type joint plate flanges used for?

- They are used in high-pressure and high-temperature systems, providing a metal-to-metal seal for a leak-proof connection.

4. Can plate flanges be used for high-pressure applications?

- Yes, raised face and ring type joint plate flanges are specifically designed for high-pressure environments.

5. What is the purpose of blind plate flanges?

- Blind plate flanges are used to close off or block pipelines or vessels, acting as a solid barrier to pressure.

6. How do I choose the right type of plate flange for my application?

- Consider the pressure, temperature, and application requirements to choose the appropriate flange type.

7. Are plate flanges easy to maintain?

- Plate flanges generally require minimal maintenance, but regular inspections are recommended to ensure they are functioning correctly.

8. What materials are commonly used for plate flanges?

- Common materials include carbon steel, stainless steel, and plastic.

9. Where can I purchase high-quality plate flanges?

- You can explore a range of plate flanges at API Flanges.

10. How can plate flanges improve the efficiency of my piping system?

- Plate flanges provide secure and reliable connections, reducing the risk of leaks and ensuring efficient operation.

Conclusion

Plate flanges are versatile and essential components in many industrial systems. Understanding the different types and their uses helps in selecting the right flange for your needs, ensuring reliability and efficiency in your piping and equipment connections. For more information or to explore our range of plate flanges, visit Texas flange